YOUR RESONATOR VACUUM PUMP NEEDS A RECONDITIONING ONCE IN EVERY 10000 HOURS. WE PROVIDE COMPLETE SEAL KIT REPLACEMENT WHICH MAKES THE PUMP WORK LIKE NEW. OUR STANDARDIZED RECONDITION FACILITY AND TEST SETUP ENSURES A CENT PERCENT QUALITY CHECK BEFORE HANDING OVER TO THE CUSTOMER. GENUINE OEM PROVIDED SPARE PARTS LIKE OIL, FILTER AND OTHERS WILL ENSURE BEST WORKING CONDITION OF YOUR MACHINE.LEI HAS REPLACED 200 OR MORE VACUUM PUMPS ALL OVER INDIA.

More about Faanuc Vaccum Cup

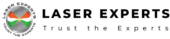

EXHAUST PUMP UNIT (OEM PART NUMBER – A90L-0001-0425)

This unit is used to vacuum–exhaust laser gas from the gas circulating system such that its pressure falls to that used for laser oscillation. Also, within this unit, a small amount of circulating gas is constantly being exchanged, to prevent degradation of the circulating gas.

When first starting the oscillator, check that gas is output from the gas outlet of the oscillator. Depending on the parameter settings, it may take as long as one minute before gas is output. If no gas is output, the exhaust pump rotation may be reversed. If this situation is left uncorrected, the exhaust pump may ultimately start to make an abnormal sound, and the thermal switch may trip. In the worst case, the gas circulating

When the operation time reaches every 4,000 hours or 2 years whichever comes first, or the exhaust capacity is lowered, replace the exhaust pump filter. A clogged exhaust pump filter may cause a whitish smoke of oil mist to come out of the pump or lower the exhaust pump capacity.

OEM SPEC. OF EXHAUST PUMP FILTER: A98L-0001-0911

Your RESONATOR Vacuum pump needs a reconditioning or replacement once in every 10000 Hours. We provide complete SEAL KIT replacement which makes the pump work like new. Our standardized Recondition Facility and test setup ensures 100% Quality check before handing over to the customer. Genuine OEN provided spare parts like OIL, FILTER etc ensures best working condition of your machine. LEI has replaced more than 200 Vacuum pumps all over India and middle east countries.

We provide 12000 Hours warranty for all our refurbished vacuum pumps all over the world

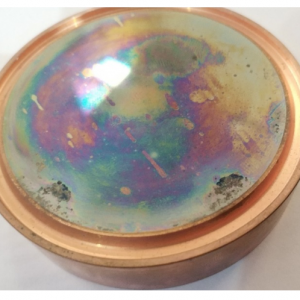

AO Mirror (Adaptive Optics) Failure Analysis:

Before Refurbishment:

Probable causes

- Improper cleaning (may have residue)

- Poor quality cleaning supplies like lens cleaner, lens cleaning tissue paper etc

- Too aggressive cleaning (scratches also)

- Poor quality lens

Beam Alignment Failure

- Beam not parallel through one or more axis, Struck the lens holder

- Beam mark not centred (or) Improper mounting of optics.

- Improper mirror alignment

Mirror Contamination

- Black discoloration proceeding towards centre may indicate a water leakage from the mirror mount, evaporating coolant in beam path or moisture in beam purge.

- Improper cleaning materials like lens cleaning tissue paper, Acetone, Ethanol will damage the coating of the mirrors and reduces the life time gradually.

- Man-handling the vacuum chamber parts like discharge tubes, mirrors will damage the parts.

- Not carrying recommended periodic maintenance like cleaning of internal mirrors once in every 3000 to 4000 Hours will leave residue in mirrors and damage the surface coating.

Beam mode

Distorted mode can generate a massive energy to be concentrated into a small spot on the mirrors, leading to a mirror explosion. In most cases, incorrect beam mode occurs because of mirror misalignment or failure in the beam delivery cooling system.

Damaged AO mirror

After Refurbishment:

Through years of analysis we found solutions overcome the failures of optics. Our unique and effective reconditioning or refurbishment method restores the optics property. Our ULTRA CLEAN method makes sure your AO mirror works like new. Thus we are able to save 75% to 85% of your optics maintenance cost. Refurbished optics used by customers all around INDIA.

Below are photos shown after our reconditioning process.